Application

BLC-UR005 Ultrasonic reactor (dispersion equipment) is a kind of equipment which is used to disperse the insoluble solid and liquid to form smaller particle mixture or suspension suspension. It can be used in the fields of new energy, medicine, cosmetics, etc. For example: catalyst, matting agent, pigment, graphite, paint coating, alumina, compound fertilizer, filler, herbicide, fungicide, powder emulsion, preparation of nano materials, food sample detection.

BLC-UR-005(5L~500L) Industrial & Lab Ultrasonic Reactor Processor|

Industrial Ultra Sonicator for Emulsifying and Dispersing

It is especially suitable for emulsification and dispersion of various nano materials or pulp (such as graphene or carbon nanotubes);

It can also be used for volatile and non-volatile extraction media, various natural active ingredients and natural products;

It is suitable for the extraction of agricultural and sideline products, melons and fruits, herbal materials, terrestrial and marine animals, plants and microorganisms;

It is suitable for the extraction of natural product ingredients needed by natural food additives, pigments, beverages, medicine, health products, etc.

Product Features

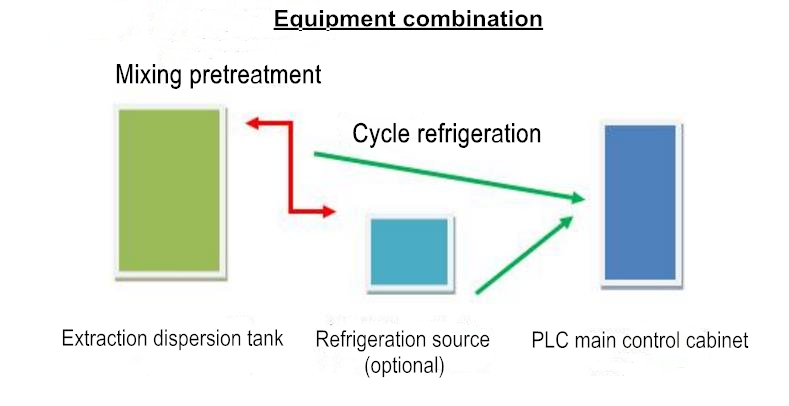

The BLC Series BLC-UR005(5L~500L) Industrial Ultrasonic Processor/ Industrial Ultra Sonicator is multi slurry internal circulation type, no dead corner in the reactor, high ultrasonic intensity, short emulsification and dispersion time, high efficiency.

1. Due to the use of cyclic enhanced ultrasound design, the material is always controlled in the range of ultrasonic field, so that the emulsification dispersion rate of the target is greatly improved.

2. It can control the dosage of all kinds of heat sensitive ingredients, so as to reduce the effective dosage of various heat sensitive ingredients, so as to achieve the goal of high temperature control.

3. The emulsification dispersion extraction time is short, which reduces other useless impurities in the extract, improves the quality of the extracted products, and lays the foundation for the separation and purification process.

4. The ultrasonic mode can be combined in many ways, including divergent, energy accumulating or combination

5. Ultrasonic frequency can be selected according to the characteristics of the sample, low frequency, medium frequency or high frequency can be used alone or at the same time. Frequency can be used in cross combination.

6. The feeding and discharging ports of the reactor can be customized according to the requirements of customers, which can be used for high-speed sample pretreatment.

7. Multi functional circulation extraction equipment, integrated precision design, light weight, small size, convenient and mobile.

8. With independent innovation design of digital integrated circuit, PLC + single chip microcomputer control, touch screen one key operating system, you can execute all kinds of instructions of the operator at will with just a little touch.

9. The temperature and other working curves can be displayed practically.

10. It can save the historical operation records and meet the GMP standard.

11. It has the function of data printing.

12. It has the function of alarm prompt and automatic protection.

13. It has the function of operation authority and password restriction.

Technical Specification

|

Model |

BLC-UR005 (5L~500L) |

|

Emulsification dispersion mode |

Cyclic multistage high density ultrasonic |

|

Ultrasonic mode |

Combination of low frequency and medium frequency multi frequency (can be used at the same time or separately) |

|

Processing Capacity |

5~500L (Stainless steel & Glass reactor) |

|

(L) |

|

|

Low frequency less than 20kHz, ultrasonic power (W) |

3000W |

|

Medium frequency higher than 28kHz, Ultrasonic power (W) |

3000W |

|

Continuous or intermittent ultrasound mode |

Yes |

|

Industrial inlet and outlet |

Yes |

|

Sample observation window |

Yes |

|

Sampling or return port |

Optional |

|

Constant temperature function |

Optional |

|

Mixing motor |

0.5kw |

|

Temperature control (℃) (optional) |

5℃ - room temperature |

|

Operation mode |

7 inch true color touch screen |

|

Monitoring curve |

Temperature curve |

|

Texture of material |

The reactor is made of sanitary stainless steel. Control cabinet (plastic spray antirust treatment) |

|

Applicable media |

Volatile or nonvolatile |

|

Purpose |

Pilot or production |

|

Processing capacity (L / h) |

5L~500L(customized) |

|

Working voltage |

AC110/220V 50/60Hz |

|

Overall dimension (mm) |

customized |

|

Landing protection |

Set the password according to the needs of users |

Note: The products can be customized according to different requirements of users.

The above pictures and data are for reference only. In case of any change, the real object shall prevail