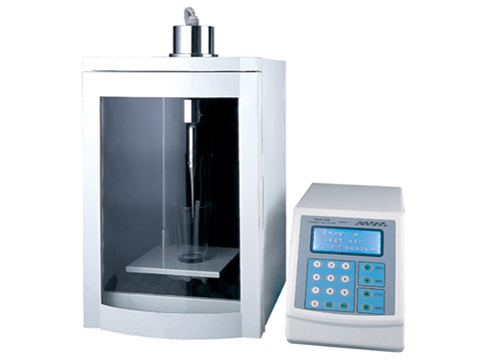

Ultrasonic dispersion | Ultrasonic processor | Probe Sonicator means that the particle suspension to be processed is placed directly in the ultrasonic field and "irradiated" with high-power ultrasonic wave, which is a dispersion method with high intensity and best effect.

Principle of Ultrasonic dispersion | Ultrasonic processor | Probe Sonicator

1. Firstly, the propagation of ultrasonic wave should be carried by medium;

2. Ultrasonic wave propagation in the medium has an alternating period of positive and negative pressure, and the medium is squeezed and pulled under positive and negative pressure of the gel;

3. When the ultrasonic wave ACTS on the medium liquid, the distance between the medium molecules in the negative pressure zone will exceed the critical molecular distance that the liquid medium remains unchanged, and the liquid medium will fracture and form micro-bubbles, which grow into cavitation bubbles.

4. Bubbles may re-dissolve in the gas, float up and disappear, or collapse out of the resonant phase of the ultrasonic field.

5. The occurrence, collapse or disappearance of cavitation bubbles in liquid medium.

6. Cavitation will generate local high temperature and pressure, and generate huge impact force and micro jet. Under its action, the surface of nano powder can be weakened, so as to realize the dispersion of nano powder.

Ultrasonic dispersion method is compared with conventional mechanical dispersion method

1. Mechanical dispersion method can be divided into:

Grinding, ordinary ball mill, vibration ball mill, colloid mill, air mill, mechanical mixing, etc. Mechanical dispersion method, many steps, the need for equipment and complex, and ultrasonic dispersion only need a power source a vibrator can be.

2. Mechanical crushing limit problem:

Due to the large interface energy of fine particles, the van der Waals force between particles is strong. With the decrease of particle size, the trend of automatic aggregation between particles becomes larger, and the dispersion and aggregation reach a balance, and the particle size no longer changes.

Therefore, when the particle size is reduced to a certain extent, the reduction rate is quite slow, which is the mechanical crushing limit of materials. Therefore, mechanical dispersion method cannot reduce the true particle size of nanomaterials, which is far less effective than ultrasonic dispersion method.

Features of Ultrasonic dispersion | Ultrasonic processor | Probe Sonicator:

1. High-power focused ultrasonic transducer is adopted, which has the characteristics of large amplitude and high conversion efficiency.

2. The ultrasonic wave with large amplitude is directly transmitted to the dispersing medium through the probe, and the dispersing effect is obvious, which greatly changes the way of ball mill used in the past and requires a lot of time to disperse.

3. The probe is made of titanium alloy with high strength, acid and alkali resistance, which can be used in various material systems.

4. Simple operation, no pollution to the treatment materials, and self-cleaning function.

5. It can continuously recycle the batch dispersion of nanomaterials, making the application of nanomaterials to the market.

6, with temperature control device, effectively avoid all kinds of materials affected by temperature

Due to the small size effect, surface effect, quantum size effect and macroscopic quantum tunneling effect, nanomaterials are different from conventional particles in thermal, optical, magnetic, sensitive properties and surface stability. How to disperse nanoparticles evenly into the matrix is one of the key technical problems of nanomaterial technology. Using the empty talk effect of ultrasound to reunite nanoparticles is currently the single most effective physical method. It is the need to deal with the particle suspension in the ultrasonic field, the use of appropriate ultrasonic oscillation and action time to deal with, our company's ultrasonic nano disperser, dispersion effect is good, power consumption is small, a single investment, long-term use, can greatly improve the performance of nanomaterials, enhance the competitiveness of products. It has become a necessary tool for many chemical manufacturers at home and abroad.

Advantages of Ultrasonic dispersion | Ultrasonic processor | Probe Sonicator:

1. Short time required for polymer homogenization.

2. Small technical capital needs;

3. The treatment has no impact on the surrounding environment;

4. Ultrasonic wave is physical and does not produce second pollution;

5. Simple structure and convenient operation.

Click here to know about Ultrasonic Processor in BuenoBiotech