Principle and Operation of Ultrasonic Processor|Ultra Sonicator|Probe Sonicator

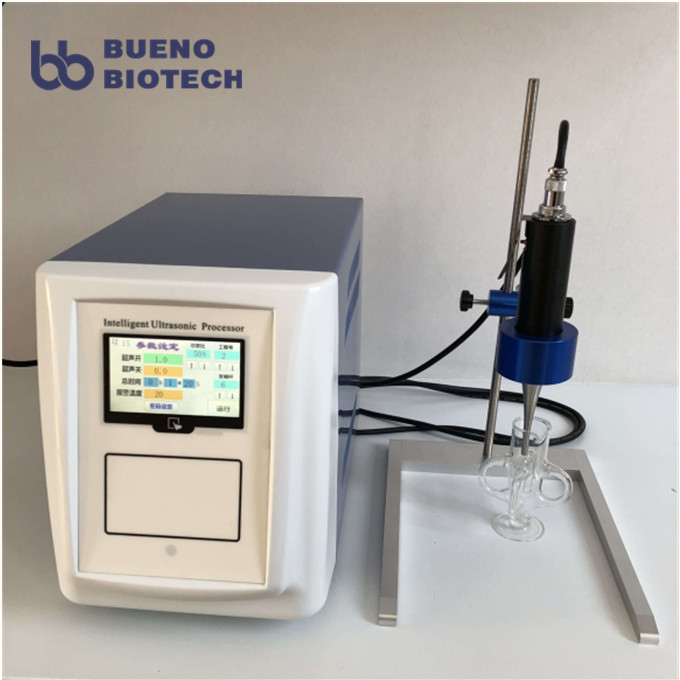

With the development of biological industry, the application of ultrasonic cell processor/ultra sonicator/ probe sonicator to do the experimental requirements are also increased, such as the sample temperature measurement, control, low temperature cooling samples and the intelligent level of the machine to improve, and so on, have put forward new requirements. Our ultrasonic processor/ultra sonicator has the advantages of advanced technology, reliable performance, simple operation, beautiful appearance, clear and bright display, accurate temperature measurement and control, etc.

Ultrasonic processor/ultrasonic disruptor/ ultra sonicator is a kind of multifunctional and multipurpose instrument which USES strong ultrasonic to produce cavitation effect in liquid and to conduct ultrasonic treatment on substance. It can be used for the breakage of animal and plant tissues, cells, bacteria and bud strains, and can be used for emulsification, separation, dispersion, homogenization, extraction, degassing, cleaning and accelerating chemical reactions, etc. Ultrasonic processor /probe sonicator is widely used in biochemistry, microbiology, pharmaceutical chemistry, surface chemistry, physics, zoology, agriculture, medicine, pharmacy and other fields of teaching, scientific research, production.

Working principle

Ultrasonic processor is composed of ultrasonic generator and ultrasonic transducer. Ultrasonic generator (power) is 220 vac, 50 hz single-phase electric pieces by the frequency converter into 20 to 25 KHZ, about 600 v alternating electrical energy, and with proper impedance matching with the power to promote the transducer, a longitudinal mechanical vibration, the vibration wave by immersed in titanium alloy for the amplitude of sample solution was broken all kinds of cells to produce cavitation effect, so as to achieve the purpose of the broken cells. Its electrical principle is composed of rectifier power supply, switching power supply, frequency conversion system, power amplifier, phase-locked frequency automatic tracker, power regulator, power detector, power protector and microcomputer control, etc.The transducer assembly is composed of piezoelectric vibrator and amplitude transformer which produces mechanical energy.

Matters needing attention

1. It is strictly prohibited to start the device when the lug is not inserted into the liquid (no load), otherwise the transducer or ultrasonic generator will be damaged.

2. The transducer shall be fixed firmly on the bracket to prevent it from sliding down suddenly from the vertical rod, and the end of the lug rod shall not collide to prevent deformation or damage.

3, The number of various broken samples, the length of time, power size, to be determined by the user according to different media grope, select the best value. (It is recommended to take samples every 5 minutes and explore the experimental conditions under the condition of working for 1 second with an interval of 1 second). If φ2, φ3, φ6 amplitude modulation bar is selected, the ultrasonic power should be set to a small, so as not to overload the amplitude modulation bar and fracture.

4, After a certain time of use, the end of the lug rod will be cavitation corrosion and hair, can be used to file the stone or file, otherwise it will affect the working effect. Many rasp, horns, shorter than it was at this time there will be a little or no ultrasonic power, at this point can be put in the rear panel select switch to the corresponding position until the normal work (at this point the amplitude and the position of the selector switch can be inconsistent, all around trying to dial to send the a ultrasonic). In this way, the use time of the luffing rod can be extended appropriately. It is recommended not to use the luffing rod for a long time, but to replace the luffing rod in time.

5, The machine does not need preheating, and it should be well grounded when used.

6. During ultrasonic crushing, due to the cavitation effect of ultrasound in the liquid, the liquid temperature will rise rapidly. Users should pay more attention to the temperature requirements of various cells.

7. The machine should be placed in a dry place without moisture, direct sunlight and corrosive gas.

8. The selection of container capacity and shape should be coordinated with the number of samples. Practice has proved that the container should be fine and long type with better crushing effect.

9. Practice has proved that: the effect of short multi-time work with working time of 1-2 seconds and clearance time of 1-2 seconds is better than that of continuous long time work. In order to prevent liquid heating, a longer clearance time can be set. In addition, uninterrupted long time work is easy to form no load, shorten the service life of the instrument.